DFT Vs. Lean

Lean: An Evolution to Process Perfection

DFT: A Revolution in Design, and THEN an Evolution to Process Perfection.

Design the line and then perfect it!

One of the most common comparisons when considering manufacturing ideologies, is between Demand Flow Technology and Lean Philosophy.

Lean takes an activity by activity approach to achieve its goal. The output of each activity is a small incremental improvement achieved through the application of the tools within the Lean toolbox. Typically, after long term implementation you will have a Lean environment where you have achieved several small incremental improvements along the way.

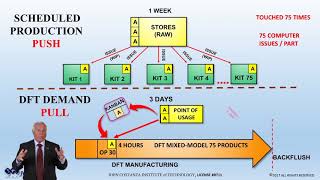

In contrast, Demand Flow Technology is a complete business strategy that looks at the entire manufacturing environment. The technology uses mathematically based tools to redesign the process and achieve an Operational Cycle Time that is based on the Demand at Capacity. This is where the differences between DFT and Lean begin.

DFT drives companies to adjust their process volume and mix every day based on actual customer demand. The demand driven technology reduces inventory and working capital costs, therefore improving speed-to-market. Demand Flow also focuses on in-process quality, forcing quality checks throughout the process, rather than at the end.

Demand Flow Technology:

Company-Wide

Technology Based

Any Model-Any Day

Sequence-of-Events Based

Eliminates Scheduling

Tools for Kanban Design

Eliminates Work Orders

Demand Driven

Designed-In-Process TQC

Total Quality OP Sheets

Flexible Workforce

Flow Based Costing

Lean Philosophy:

Philosophical/Evolving

Labor Focused

Discuss Philosophy…Implement Technology

Comments