Taiichi Ohno: Seven Wastes Model

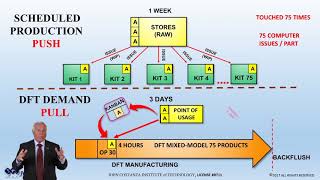

A Direct Shot at Scheduled Production

Eastern manufacturing, predominately companies in Japan and Korea, continue to prefer the Flow and pull Manufacturing approach. Taiichi Ohno, was the creator and leader of the Toyota Kanban Demand pull system and he stated that he preferred the West’s “supermarket” approach as opposed to their manufacturing scheduling techniques. The supermarket approach became the foundation for the Toyota material pull system and Kanban.

His seven wastes model (Muda in Japanese) took a direct shot at scheduled production. Yet, the philosophical lean and waste eliminators ignored the scheduling aspect and used Muda as their model for the “secrets” of Japanese improvement. They missed the forest for the trees.

When we look at the seven elements of waste and associate each of them to scheduling, we see an interesting relationship:

1. Waste: Delay, waiting, or time spent in a queue with no value being added.

Scheduling lead time has a queue and wait time designed into it.

2. Waste: Producing more than you need.

Scheduling is lot quantity based, and Flow production is single-piece Flow focused.

3. Waste: Over-processing or undertaking non-value-added activity.

No value is added in the entire scheduling, material issuing, or kitting processes. However, nothing happens in scheduled production without a schedule. In DFT, we will complete a sequence of events (S.O.E.) and classify work as value or non-value added. The non-value-added work is removed in the Flow manufacturing line design.

4. Waste: Transportation.

Unnecessary movement and touching of parts for the ERP kitting process as well as the production departmental routing is a waste of quality and transportation. In the DFT line design, the S.O.E. identifies and classifies all transportation as non-value-added move time. Once they are identified they can be eliminated in line design.

5. Waste: Unnecessary movement or motion.

In the Flow process design, unnecessary set-up and move times are defined and eliminated. Move time is traditionally defined in the ERP routings and is part of the scheduling lead time, days. In DFT, every step is classified as to its added value. We try to eliminate non-valued-added work, set-up and move time in the Flow line design.

6. Waste: Inventory.

Waste of inventory is equated to unnecessary working capital and single-digit inventory turns. With the DFT line design, work is chained together in a single piece Flow process. This allows products to go through the manufacturing process in minutes and hours instead of days associated with scheduled production. The corresponding in-process inventory will drop substantially. Demand Driven production has a major impact on eliminating unnecessary finished goods.

7. Waste: Production of defects.

In DFT, quality is designed into each operation. Quality criteria is defined for each step of production. Visual DFT Operational Method Sheets have parts-per-million, in-process quality designed into each operation.

Flow manufacturers started by designing a single piece Flow process, and then continued to improve on their Flow manufacturing foundation. Process Perfection is continuously refining in-process quality, eliminating non-value steps in the sequence of events, improving productivity, reducing overhead structures and increasing inventory turnover.

Transitioning to DFT takes work, but the benefits are unparalleled. Specific products and processes do not matter; it is simply a question of leadership and teamwork to make it happen.

We should stop following every philosophical or Japanese buzzword for islands of process improvement and waste elimination, i.e. muda, hoshin, lean, kanri, Kaizen, Kung Fu, etc. Instead, we should start by designing a Flow and Pull process.

Schedule-based, lean and waste elimination manufacturers would be better served by designing an optimal start-to-end pull process rather than trying to improve a flawed scheduling foundation. If it weren’t so alarming, it would be amusing to see a schedule-based company performing a Kaizen event to improve labor productivity and eliminate waste. Their inspection workforce is approaching production in size and their inventory turnover is still in the single digits. Labor productivity is important, but when it is 8% of your product cost, how about also focusing on the other 92% as well?

Continuous process improvement is always beneficial, but it is misleading to make companies believe they can evolve from scheduling to a more competitive Demand Driven Flow manufacturing company.

Comments